Aluminum alloy A5052 – H32 is an aluminum made of two main components: Cr (0.15-0.35%) and Mg (2.20-2.80%) to help enhance corrosion resistance, so it has become a type of aluminum that is resistant to corrosion. Rust is the most widely used today.

Aluminum alloy 5052 – H32 has average strength, good thermal conductivity, excellent formability and weld resistance, so it is used for decks, ship walls, covering yachts and cruise ships, tanker body, tank body, bus body, …

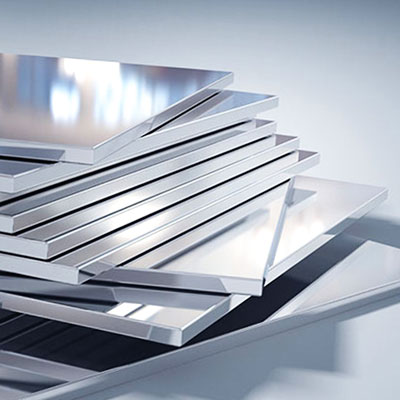

Thickness: 1 – 100 (mm)

Dimensions: 1220 x 2440, 1250 x 2500, 1500 x 3000 (mm)

Temper: H32

Weight: L x W x H x 2.72/1000000 (Kg)

Origin: China, Japan, Korea, some EU countries meeting ASTM and JIS standards.

In addition to this size, Fortune Company also provides many sizes according to customer requirements.

Fortune Import-Export Co., Ltd has a large warehouse, large product output, and is proud to be a professional aluminum importer, exporter and distributor that meets the needs of quality and size, ensuring the best product supply. for customers.

Preferential policy when purchasing

- The most competitive prices now

- Commitment to genuine products

- Ensure goods are always stable

- CO-CQ certification of the factory

- Fast shipping

- Diverse products, dedicated service

Fortune Import-Export Co., Ltd

Address: No. 07 Song Da, Ward 2, Tan Binh District, HCM City

Phone: (028) 3868 7872/73/74

Email: sales.admin@fortune.com.vn

Website: https://aluminium.com.vn/

Chemical composition

| Magnesium (Mg) |

2.20-2.80% |

| Chromium (Cr) |

0.15-0.35% |

| Iron (Fe) |

0.40% |

| Silicon (Si) |

0.25% |

| Copper (Cu) |

0.10% |

| Zinc (Zn) |

0.10% |

| Manganese (Mn) |

0.10% |

| Other |

0.05% |

| Aluminium (Al) |

Còn lại |

Mechanical Properties

| Temper |

Specified thickness

mm |

Tensile strength

Rm

MPa |

Yield

strength

Rp0,2

Mpa |

Elongation min

%. |

Bend radiusa |

Hardness

HBWa |

| over |

up to |

min. |

max. |

min. |

max. |

A50mm |

A |

180o |

90o |

|

| H32 |

0,2 |

0,5 |

210 |

260 |

130 |

|

5 |

|

1,5t |

0,5t |

61 |

| 0,5 |

1,5 |

210 |

260 |

130 |

|

6 |

|

1,5t |

1,0t |

61 |

| 1,5 |

3,0 |

210 |

260 |

130 |

|

7 |

|

1,5t |

1,5t |

61 |

| 3,0 |

6,0 |

210 |

260 |

130 |

|

10 |

|

|

1,5t |

61 |

| 6,0 |

12,5 |

210 |

260 |

130 |

|

12 |

|

|

2,5t |

61 |

| 12,5 |

40,0 |

210 |

260 |

130 |

|

|

12 |

|

|

61 |

- Boiling temperature is about 650℃

- Thermal expansion reaches 23.7 x 10^6/K

- Maximum elasticity 70 GPa

- Has a thermal conductivity coefficient of up to 138 W/m.K

- Has a resistance of about 0.0495 x 10^6 Ω .m

- The lowest pressure level for destruction is 130 Mpa

- Tensile strength level is about 210 – 260 Mpa or more.

Aluminum alloy A5052 – H32 is widely used in industrial and mechanical CNC industries such as: making shipbuilding accessories, building boat hulls, canoes, manufacturing food processing equipment in the nutrition industry, manufacturing truck components such as truck bodies, vehicle accessories, materials for aircraft processing, car manufacturing, etc.

In addition, this aluminum alloy is also used in civil applications such as: manufacturing household appliances, cooking utensils, kitchen equipment, etc.

In the construction field: architectural lighting, used to make molds for plastic molding, making hanging light troughs, raw materials for making traffic signs, car license plates, cars, …